The Science of Temperature Sensor Location

Learn why air temperature is the controllable factor influencing product temperature

A common question we get from Sensitech® customers is why our sensors monitor trailer temperature instead of product temperature. There is a good answer, but to get there we need to explore the science of temperature sensor location and placement .

Product Considerations for Temperature Sensor Location

Before getting to the temperature sensors, we need to look at the product itself. There are several factors and practical considerations that can strongly influence the product’s thermal behavior during transit:

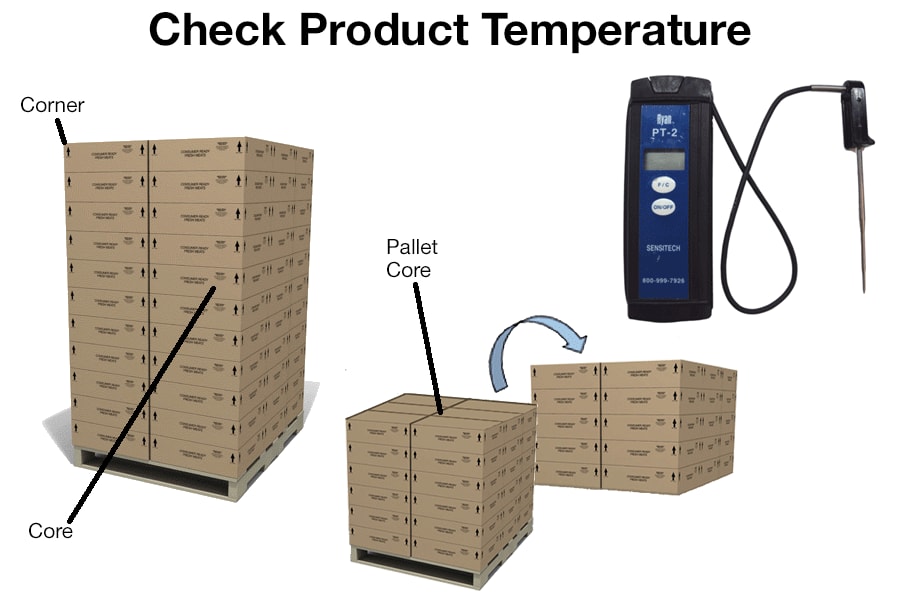

- The temperature at loading is often not uniform between pallets or even between boxes on the same pallet, making it difficult to get a consistent temperature reading on a single pallet.

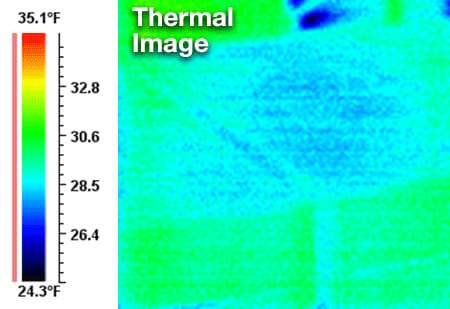

- When the trailer’s air temperature changes, it causes temperature variations on the outer surfaces of boxes and pallets. These surfaces tend to be where temperature excursions occur. Temperature probes in the core of a product, box or pallet often masks temperature changes occurring in these exposed locations, providing a misleading view of what is actually happening to the product.

- Location of the product within the box and pallet as well as the location of the box within the pallet and the pallet within the trailer.

Food industry professionals are trained to look carefully at product temperature and intervene to prevent temperature excursions. Before loading, ensure that entire trailer has reached the proper product temperature. (see Sensitech’s Maintain Cold Chain Food Safety with Four Simple Steps); however, focusing on product temperature alone during transport results in undetected temperature excursions and missed opportunities to improve processes.

Why Change the Temperature Sensor Location from Product to Trailer

Product temperature is important, but measuring one or even a handful of products in a shipment one or a very limited number of product locations will generally provide a misleading and ultimately confusing impression of what is happening. By changing the temperature sensor location from the product to the trailer itself, we are better able to identify at-risk products. Measuring trailer air temperature tells us more than the temperature of a specific box of product on that load.

Air temperature is directly correlated to the primary factor that affects product temperature. Measuring it gives us an understanding of what is causing product’s temperature changes and better reflects the overall temperature performance of the load.

Moving the temperature sensor location to the trailer’s wall, specifically near the rear door, makes it easier to identify temperature fluctuations caused by extended door openings, refrigeration unit malfunctions, incorrect refrigeration unit settings, etc.

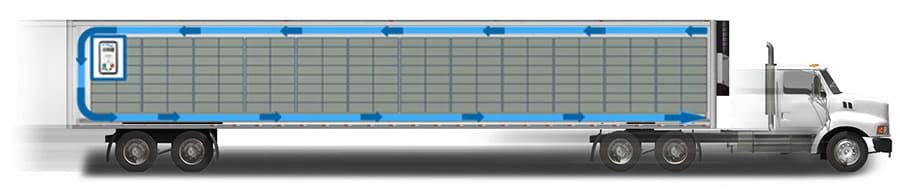

Additionally, the reefer unit is placed at the front of the trailer, so placing the temperature sensor at the back can identify poor airflow and ease the challenges of reefer trailer temperature monitoring.

How Optimal Temperature Sensor Location Provides Actionable Insights

When it comes to product temperature, there’s only one factor you can control while in transit, and that’s air temperature. If you a product’s temperature is close to an excursion, you can adjust the air temperature to prevent it.

If the loading temperature is good and the air temperature and circulation are maintained properly, the outcome for the entire load will be good. When measuring trailer air temperature, consider your temperature sensor location and ensure there’s enough temperature buffer for allowances such as reasonable door openings and defrost cycles in the setting of the monitor alarm specifications and in the interpretation of the graphs.

To learn more about how our project team can worth with your business to assess risk and find solutions, Contact Us today.