Reviewing Recent Changes to USP <1079>

In December 2020, The United States Pharmacopeia (USP) adopted changes to key chapters of their quality standards.. While these changes have been in effect for some time now, it is important that all life sciences companies brush up on these recommendations and understand why these changes to storage and distribution practices were necessary.

How Has USP <1079> Changed?

The changes to USP <1079> are significant and outline the need for all companies who will store, handle, or transport products with label temperature requirements to meet a thorough Quality Management System (QMS).

USP <1079> outlines good storage and distribution practices for temperature-sensitive drugs during all stages of the cold chain. To demonstrate this change, the chapter title changed from “Good Storage and Distribution for Drug Products.” to “Risks and Mitigation Strategies for the Storage and Transportation of Finished Drug Products.”

Significant Changes to USP <1079>

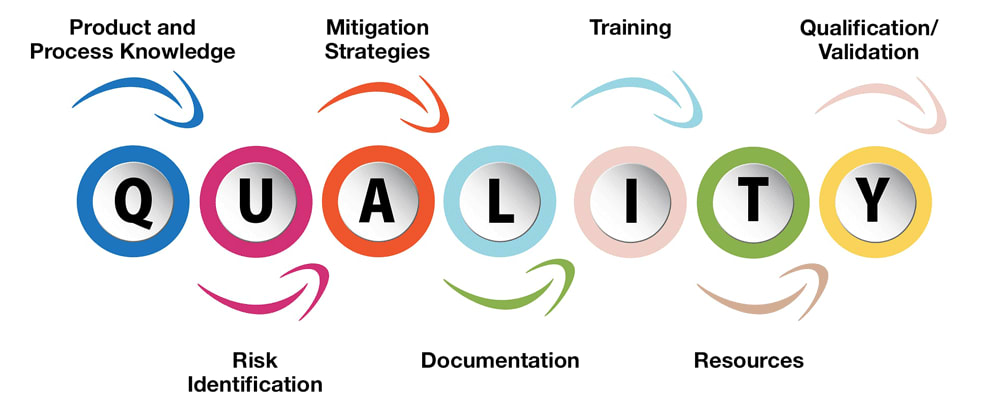

The 2020 updates to USP <1079> focus on product and process knowledge, risk identification, mitigation strategies, documentation, training, resources, and qualification/validation, all leading to a well-designed Quality Management System (QMS). One of the significant changes is a new chapter outlining the Roles of Organizations within the Supply Chain. It specifically defines the responsibilities of manufacturers, wholesalers, distributors, pharmacies, compounding pharmacies, hospitals, healthcare providers, brokers and logistics providers.

Additionally, USP <1079> now defines the requirements of all partners within the supply chain, from manufacturer to last-mile pharmacy, and the responsibilities that all must follow to protect the product and ensure patient success. These responsibilities relate to qualification and validation such as temperature mapping, shipping package qualification, monitoring systems and alarms, software validation, calibration, excursion handling and training.

Another notable change is that the product temperature definition that was formerly in USP <1079> now resides in chapter USP <659>.

Sub-Chapter USP <1079.2>

The 2020 changes also created a new sub-chapter to USP <1079> called USP <1079.2> “Mean Kinetic Temperature in the Evaluation of Temperature Excursions during Storage and Transportation of Drug Products.”

USP <1079.2> is just one of seven new sub-chapters added in 2020. The others include:

- USP <1079.1>: Storage and Transportation of Investigational Drug Products

- USP <1079.2>: Mean Kinetic Temperature in the Evaluation of Temperature Excursions during Storage and Transportation of Drug Products

- USP <1079.3>: Monitoring Devices – Time, Temperature, and Humidity (will replace USP <1118>)

- USP <1079.4>: Qualification of Storage Areas

- USP <1079.5>: Qualification of Shipping Systems

- USP <1079.6>: Transport Route Profiling Qualification

- USP <1079.7>: Information Systems for Distribution Validation / Verification Studies

Why USP <1079.2> Matters

In this final section, we will clearly define sub-chapter USP <1079.2> Mean Kinetic Temperature. These changes have significantly impacted best practices for pharmacological storage and distribution and it is important to understand why they exist and some of the challenges in adopting them.

USP <1079.2> Mean Kinetic Temperature Defined

USP <1079> outlines good storage and distribution practices for temperature-sensitive drugs across all stages of the supply chain. USP <1079.2> is a new sub-chapter providing more guidance around Mean Kinetic Temperature (MKT).

Mean Kinetic Temperature expresses the cumulative thermal variability experienced by a product during storage and distribution. Excessive thermal variability will result in an unacceptable MKT value.

Mean Kinetic Temperature Challenges

Tracking MKT isn’t new. Many in the pharmaceutical industry are familiar with it and conversations tend to be centered around three main topics:

- How much temperature data is too much when calculating MKT?

- Can MKT only be used for storage or can it also be used within transportation?

- Can MKT only be used for Controlled Room Temperature (CRT) products or can it also be used for refrigerated products?

The new sub-chapter, USP <1079.2>, defines limiting how much data to use when calculating MKT, along with an explanation of its use for transportation and refrigerated shipments.

Until recently, many organizations used 52 weeks of temperature data to calculate MKT. For the Storage of CRT products, USP <1079.2> defines that a maximum of 30 days of temperature data may be used for the calculation of MKT. Similarly, for the new refrigerated temperature category called “Controlled Cold Temperature,” only 24 hours of data during transportation may be used to calculate MKT.

The Benefit of USP <1079.2>

The goal of the new sub-chapter is to limit the amount of data used and the time period in MKT calculation -- calculating over a longer time period increases the amount of data used, which can potentially dilute the results and create acceptable MKT values, when the product actually may have been temperature abused.

By limiting the timeframe of data used to calculate MKT (maximum of 30 days), MKT values better depict the actual temperature a product may experience during storage or transportation.

Get Accurate Temperature Readings With Sensitech

Collecting accurate temperature data is the first step in adhering to USP best practices. Sensitech’s real-time temperature monitors and SensiWatch platform enable pharmaceutical organizations to accurately track their data over time and ensure product integrity.

If you would like more information on Sensitech’s thermal mapping studies, Contact Us today.