Temperature Control on the Transportation of Flowers

Understanding the Temperature-Controlled Flower Supply Chain to Ensure Product Quality

All temperature-controlled supply chains are not created equal. Fresh-cut flowers are a unique commodity with specific needs—which means distributors need an explicit understanding of their supply chain.

For example, because flowers are delicate and valued for their visual beauty, proper temperature maintenance during transport is essential. Any improper handling can dramatically reduce shelf life, vase life, and product quality.

In addition, the flower market experiences several major peak seasons, particularly around holidays like Valentine’s Day and Mother’s Day. A shipment loss during a period of high demand can cause huge disruptions. When it comes to temperature control and transportation of flowers, there is little room for uncertainty.

What Temperature Do You Transport Flowers?

Flowers are extremely sensitive to temperature changes. Cut flowers start to wilt at temperature changes as small as 2 degrees Fahrenheit and some varieties are more sensitive than others. Therefore, it’s critical to know the ideal temperature for each floral product before sending them off.

Bulbs

Bulbs are more robust and less sensitive to temperature changes than other flowers. After all, the Dutch of the 1600s transported tulip bulbs across the Atlantic in wooden crates without any temperature control at all. That said, bulbs are more likely to survive transportation when they are kept in a low-humidity environment between 40°F and 63°F.

Humidity control is critical when transporting bulbs. High humidity can cause water to condense on the bulbs, potentially damaging them and increasing the likelihood of any present disease spreading through the stock. For this reason, bulbs should be ventilated throughout the supply chain.

Cut Flowers

Like any other plant, cut flowers benefit from increased longevity at cold temperatures. However, because cut flowers are more delicate than the average fruit or vegetable, they must be kept at near-freezing temperatures and are sensitive to even slight temperature changes.

Non-tropical cut flowers have an optimal storage temperature of 33°F to 35°F. Most flowers start wilting at 37°F, so precision temperature control and temperature monitoring are critical. Tropical flowers (such as tropical orchids) are less sensitive to slight temperature changes but can be damaged at the low temperatures required by other flowers. Generally, tropical flowers should be stored between 50°F to 55°F.

Potted Plants and Flowers

Transporting potted plants is similar to transporting cut flowers, except that they require some micromanaging before shipping. Temperature-wise, the same guidelines apply. Most potted plants should be kept at 33°F to 35°F. However, tropical plants and others that normally grow in a hot and humid environment are better suited to the 50°F to 55°F range.

For optimal results when shipping live plants, remember to

- Gradually reduce light levels by 75% over several weeks

- Increase soil water content to 50% immediately prior to transportation

Risks in Flower Cold Chain Logistics

The majority of non-chilling sensitive flower varieties should be maintained at temperatures between 0°C and 1°C (32°–34°F). Deviations from this range can quickly reduce vase life and quality, as flowers respond almost immediately to their ambient environment. For this reason, rapid cooling and constant, adequate temperature maintenance throughout the entire flower cold chain are essential to reduce quality issues, such as:

- Increased respiration rates

- Gray mold (Botrytis cinerea)

- Wilting

- Early senescence (biological aging)

The high export value and seasonality of fresh-cut flowers makes temperature monitoring during transport and distribution particularly important. During holiday-related peak seasons, shipment loss can be costly and result in a lack of required stock levels, as many distributors do not have replacement shipments available.

Identifying Cold Chain Breaks

Temperature maintenance of ground-transported and air-freighted flowers is difficult, which is why temperature abuse (such as flowers being poorly pre-cooled or excessively cooled) is common in the industry. Careful temperature control on the transportation and distribution of fresh-cut flowers is a multi-step process with many areas for potential cold chain breaks including:

- Harvesting

- Cooling facilities

- Ground or air transit

- Cross docks

- Distribution centers

- Retailers

Understanding exactly when and where temperature issues are occurring in the supply chain is valuable for driving continuous improvement and increasing product quality, ultimately increasing profit margins and brand integrity.

Use Case: Temperature Monitoring the Flower Supply Chain

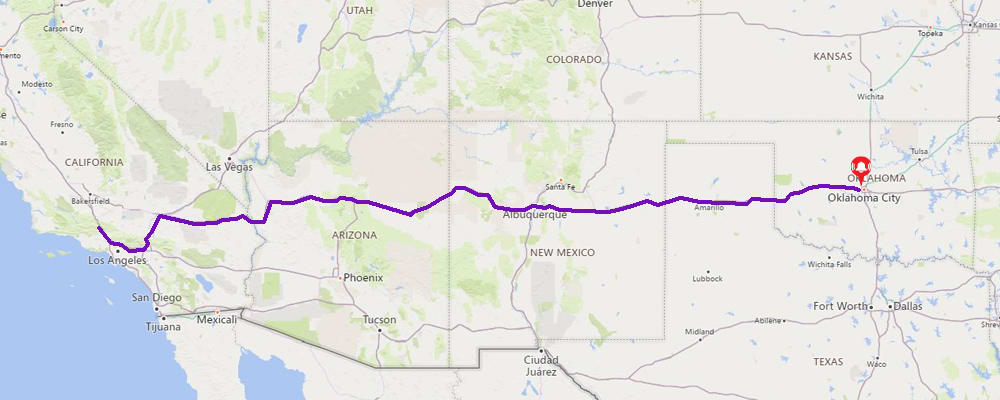

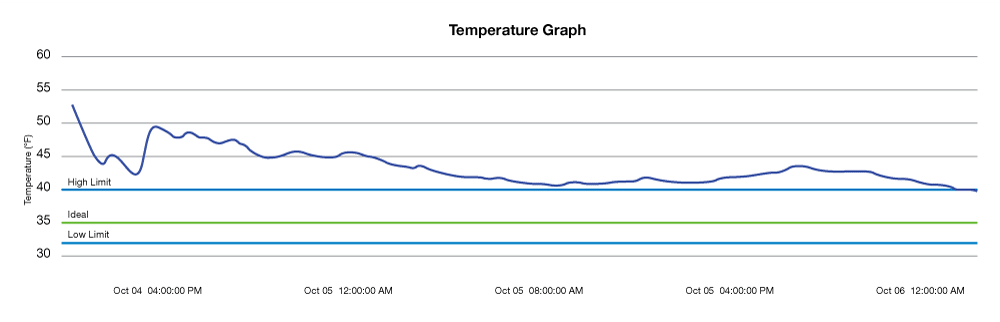

Above: The temperature graph and map displays real-time ambient temperature and location data collected by a TempTale® GEO monitor during a shipment of fresh-cut flowers. High, ideal, and low temperature limits are determined by the customer based on commodity.

Sensitech’s TempTale® GEO monitors are perfect for the floral industry, monitoring shipments and identifying deviations in the cold chain before product quality is impacted. These monitors provide real-time temperature and location visibility, allowing shippers, receivers, or transportation providers to know exactly where and when deviations occur and react to them in real-time.

For example in the U.S. in 2015, one customer monitored 700 shipments of cut flowers using the TempTale GEO datalogger. Of those shipments, 59% triggered high- temperature alarms. High and low temperature alarms are triggered when ambient temperature specifications for the shipment exceed a programmable threshold. Real-time alarms allow customers to react immediately, preventing damage or product loss.

In a separate case, a supplier used TempTale GEO monitors to identify an issue in the flower cold chain by tracking shipments all the way to the retailer, where it was determined that the flowers were being held at improper temperatures at a critical hand-off in-transit. The product was being re-palletized over a five-hour period, at a cross-docking facility whose dock temperatures were 12.8°C (55°F). As a result, flower temperature spiked more than 10 degrees during that portion of the cold chain.

Another flower supplier, using the TempTale GEO monitors in Europe, discovered that flowers were being exposed to chilling temperatures during transit from the packing facility to the store. The use of the TempTale GEO dataloggers by these two suppliers provided visibility and allowed them to determine exactly where temperature abuse was occurring.

Improve Your Flowers Cold Chain with Sensitech

Maintaining adequate temperature control during the transportation of fresh-cut flowers is critical to help reduce post-harvest disorders, ensure quality and vase life, and maximize profit. Real-time temperature monitoring is a powerful way to make improvements to the cold chain both during and after transportation, reducing the risk of damaging a valuable and sensitive commodity.

To learn more on how to optimize the supply chain, Contact Us today.